leaf republic

Engineering, Product Design

We love to beautifully present things, to beautifully package them. As the number of people and their consumption keep on growing, it is time to revolutionize it.

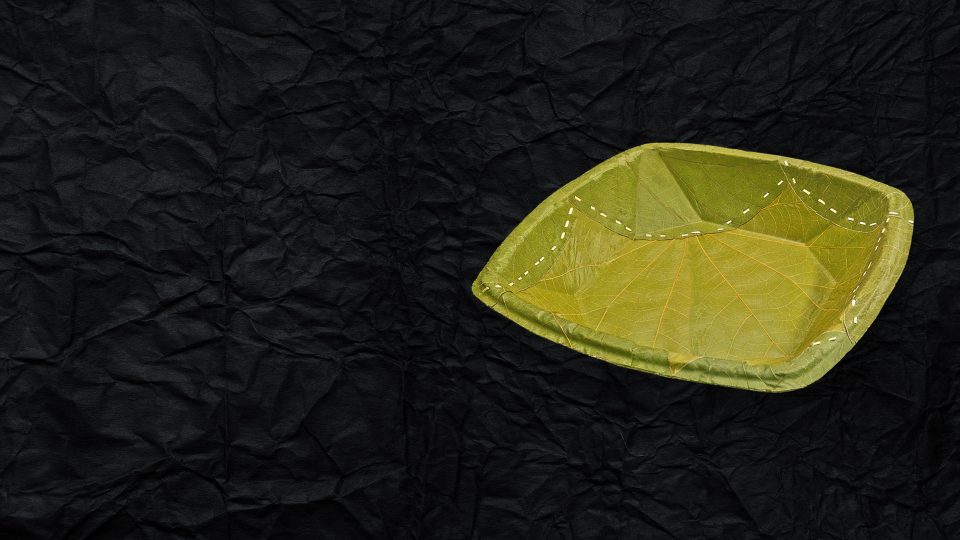

The result is made of 100% natural components and is a select item in Die Neue Sammlung, the design museum at Pinakothek der Moderne.

Background

leaf republic was a German company that produced eco-friendly tableware and packaging made from leaves. Founded in Munich, the company offered a range of biodegradable bowls, trays, and plates in various shapes and sizes. The company was inspired by traditional leaf plates used in Indian culture and aimed to bring this eco-friendly solution to the global market.

Scope

Leaf Republic’s primary goal was to create sustainable and biodegradable tableware as an eco-friendly alternative to traditional disposable products. The company aimed to:

-

Develop fully renewable and biodegradable outdoor tableware and packaging that that decompose within 28 days, leaving minimal environmental impact.

-

Revolutionize the packaging industry by offering a 100% compostable solution without using any synthetic additives, chemicals, or glues.

-

Reduce plastic waste and prevent trees from being cut for paper production.

Challenge

As the CTO at leaf republic, I faced numerous challenges in bringing our innovative leaf-based packaging solutions to market. My team and I worked tirelessly to transform our concept into a market-ready product within just a few months. This rapid development required me to lead the creation of novel forming, material handling and adjacent processes and oversee the design of specialized machinery essential for our unique production needs.

Technology

Leaf republic’s technology incorporated a unique three-layer design to achieve waterproofing: The plates consisted of two layers of leaves stitched together with palm leaf fibres, and a waterproof layer of leaf-based paper in between. This innovate middle layer guaranteed the water resistance necessary for the plates to function in various demanding packaging scenarios. The the usage of leaf-based paper made of upcycled cutting waste allowed the company to maintain its commitment to using only natural materials and a zero-waste policy.

Execution

Bringing the concept to market readiness within just a few months required efficient and agile project management and innovation. On the operational side, conceptualizing and developing complex pressing moulds and in-line tools for material preparation to shape the product was a critical aspect of the manufacturing process. At the same time, optimizing machine control systems and building sensible material handling solutions ensured reliable automation despite highly variable parameters of the organic materials.

Success story

Our breakthrough allowed us to secure major clients, like Aldi Süd, demonstrating the commercial viability of our products. We didn’t stop there; by customizing product properties thanks to our flexible design and production processes, we were able to expand into new market segments, broadening our impact in the sustainable packaging industry.